UNLOCKING THE VAST POTENTIAL OF THE LITHIUM METAL BATTERY

PURE LITHIUM’S NEXT GENERATION BATTERY

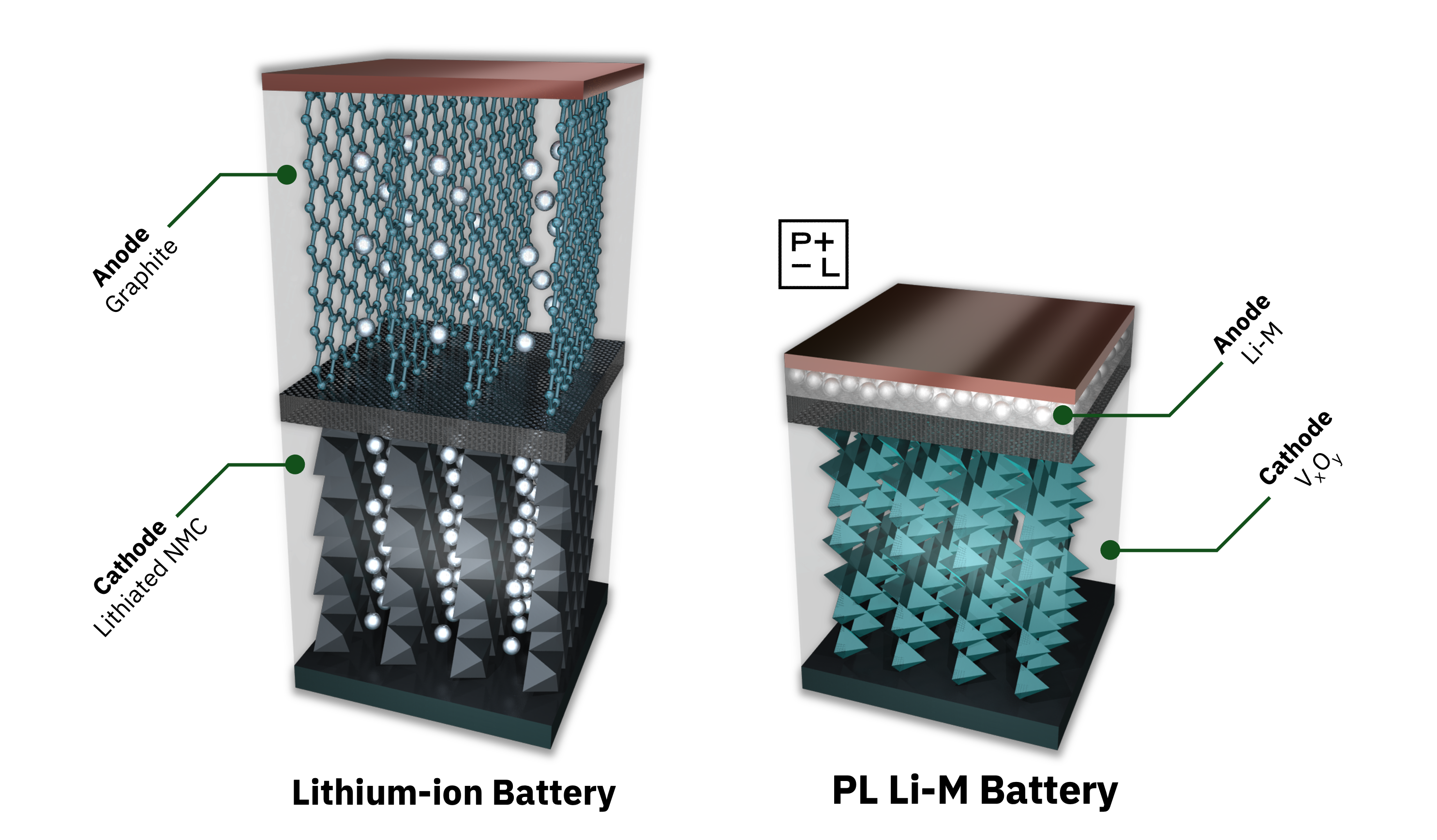

We pair our lithium metal anode with a vanadium cathode, creating a next-generation battery that has achieved over 1,300 cycles at commercially relevant charge rates of 1C and 1D.

This superior alternative to today’s lithium-ion battery is much more fire resistant thanks to the vanadium cathode’s ability to function at temperatures of up to 700⁰C.

robust Intellectual Property

Pure Lithium shares a joint patent application with battery pioneer Sir M. Stanley Whittingham, pairing our lithium metal anode with his vanadium-phosphate cathode. Professor Whittingham won the 2019 Nobel Prize in Chemistry for the invention of the lithium-ion battery.

lithium metal vs lithium ion

The holy grail of energy storage

Lithium metal offers about 10 times the capacity of a lithium-ion graphite electrode. Until now, cost, quality and environmental issues have made it impossible to produce a commercially viable lithium metal battery.

Unable to meet the growing energy storage demand

Today’s lithium-ion batteries were never meant to meet the world’s energy storage demands. They were invented for a Sony camcorder and are not fit for purpose for EVs and grid-scale energy storage among other applications.

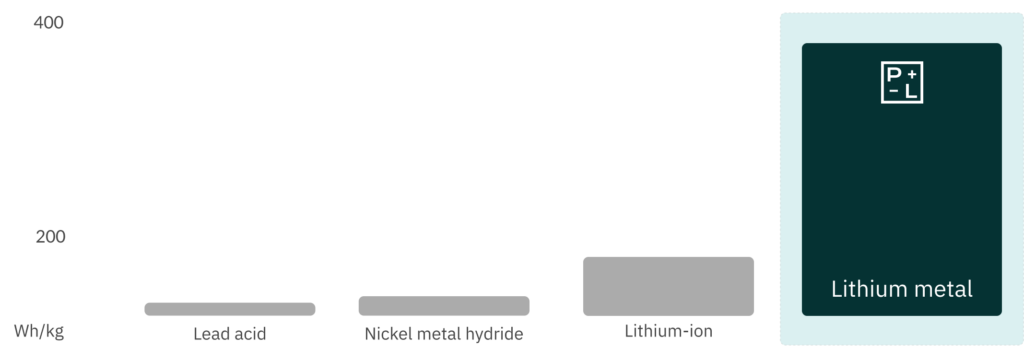

a STEP CHANGE IN ENERGY DENSITY

Higher energy density means more energy can be stored in a smaller space, reducing battery size and weight while improving duration.

Only two batteries in our lifetimes have been commercialized to gigawatt scale: lead acid and lithium-ion.

Lithium metal will be next and will supplant the lithium-ion battery.

BRINE TO BATTERY™ REVOLUTIONIZES PRODUCTION

Our Brine to Battery™ technology enables the fast and inexpensive manufacturing of a battery-ready lithium metal anode, bypassing traditional lithium compound production.

We inexpensively electrodeposit highly pure lithium metal onto copper from widely available brine, creating a full battery anode in a single step that costs a fraction of existing lithium metal production.

We are the only company to achieve lithium metal extraction and anode production, enabling fast and inexpensive manufacturing at a commercially viable price of $15/kWh.

Brine

Pure Lithium extracts lithium from lithium-bearing brine.

Lithium Metal Electrodeposition

Pure Lithium’s proprietary polymer membrane conducts only lithium and protects the lithium metal anode from water. Our process deposits ultra-thin, 99.9% pure lithium metal onto a substrate directly from brine. This is completely different than direct lithium extraction (DLE), which cannot produce lithium metal.

Lithium Metal Anode

Lithium metal offers a tenfold increase in energy capacity compared with graphite found in today’s lithium-ion anodes, drastically reducing battery weight and volume.

Vanadium Cathode

Vanadium is the fifth most common transition metal in the world and is frequently found in the same regions as lithium, including North America. The vanadium cathode provides a 50% increase in capacity compared with lithium iron phosphate (LFP) cathodes used in lithium-ion batteries and does not contain lithium, driving down costs. The cathode is stable up to temperatures of 700⁰C, mitigating thermal runaway.

Battery Assembly

The complete battery is assembled at a single vertically integrated facility, allowing Pure Lithium to locate the entire process at the source of lithium brine. The battery is assembled in a charged state.

Slashing lithium metal Production Costs

Ingot Extrusion

Ingot extrusion uses a costly and high-temperature process known as molten salt electrolysis to create a lithium ingot. This is put under immense pressure to mold it into a foil that is then rolled and pressed onto copper foil, resulting in a poorly constructed lithium metal anode. The process costs $3,650/kWh and results in surface defects, significant scrap, poor adhesion and thickness limitations

Physical Vapor Deposition

Physical Vapor Deposition takes lithium metal ingots and vaporizes them under a vacuum into a gaseous state. Li is then directed towards a copper substrate and deposited atom by atom until a thin foil is formed. PVD is a very slow and expensive process at $660/kWh and cannot be scaled up to a commercial level

pure lithium method

Pure Lithium’s electrodeposition process extracts lithium from brine at room temperature with the help of our proprietary polymer technology. We deposit ultra-pure lithium metal of tunable thickness onto a substrate, producing a battery-ready anode. The process reduces energy and water consumption and costs just $15/kWh