Enabling Lithium Metal Battery Technology

From the Ground to the Battery

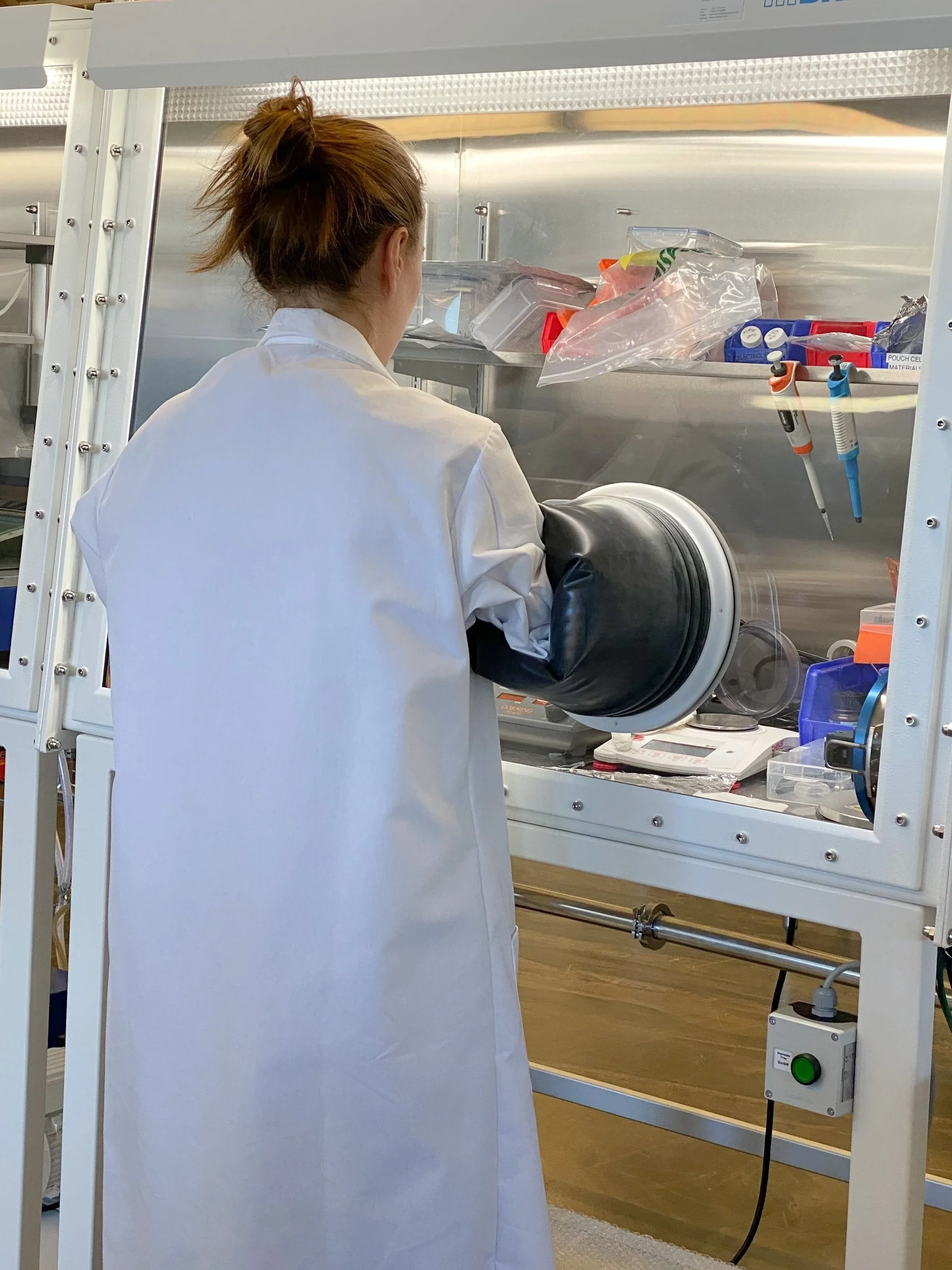

Battery ready lithium metal electrodes for the next generation of energy storage

We’ve invented the first battery-ready pure lithium metal electrode made from a variety of inexpensive, available lithium salts. We use electrons to create ultra-thin lithium metal electrodes for next-generation batteries. Our technology eliminates 90% of the costs involved with traditional lithium metal foil production and, for the first time, produces a protected battery-ready electrode of unprecedented quality and purity paving the way to lithium metal batteries for less than $50 kWh.

A non-flammable, next-generation battery

Our next-generation batteries in development are designed to truly disrupt. We’ve invented the first rechargeable non-flammable lithium metal battery utilizing Pure Lithium’s electrode, polymer, and inorganic liquid electrolytes.

We only pursue chemistries that meet the following criteria:

● Over 400 Wh/kg

● Non-flammable

● No Nickel or Cobalt

● Readily available materials

● Under $50 kWh

Completed electrode

Pure Lithium is the first and only technology company producing a battery-ready pure lithium metal electrode from readily available lithium salts, paving the way for the mass adoption of EVs.

Viable supply chaiN

Our patent-pending technology allows for the use of a variety of lithium salts, allowing Pure Lithium to establish a fully domestic supply chain for next-generation lithium metal batteries while driving down the per-ton cost of lithium metal by orders of magnitude.

Non-flammable Battery technology

Our electrodes and batteries use our proprietary solid polymer electrolyte that is non-flammable. Our batteries are made with a combination of our electrodes and our non-flammable inorganic liquid electrolytes.

Efficient sustainable technology

Pure Lithium’s technology goes from lithium salts to pure lithium metal electrodes in one step using a range of inexpensive available feedstocks. The low cost and dramatically improved product pave the way for the mass adoption of EVs.

Lithium metal is the Holy Grail of energy storage

Li-ion technology can’t meet the growing energy demand

To meet the challenges of energy

production and the climate crisis, we must use lithium differently. Today’s Li-ion batteries

cannot meet the world’s energy demands and were never meant to do so. Now, they are

straining the world’s cobalt and nickel supplies.

Lithium metal is the “holy grail” of energy storage offering 3860 mAh/g of capacity compared to today’s Li-ion graphite electrode containing 372 mAh/g. Pure Lithium has solved the problems plaguing the adoption of this game-changing technology.

-

Today’s process for producing lithium metal is a century old and uses lithium chloride as a precursor. Process requires extremely high temperatures (500-700°C) generating toxic chlorine gas and halide salts. Processing has been relegated to countries with weak environmental regulation, and the product is an extruded foil that is insufficient for rechargeable lithium metal batteries.

-

Lithium metal is not produced in a battery-ready form today. A lithium foil is not an electrode. Cell manufacturers purchase thick extruded lithium foil from Asia and then have to commit time and resources to mechanically fuse the foil to a substrate. The lithium arrives coated with mineral oil after being exposed to air which severely compromises the integrity of the lithium, and it is not sufficient for rechargeable batteries. The price of metal is between $160 - $180,000 per metric tonne which is unrealistic.

-

Our patent portfolio includes technology to produce electrodes at battery manufacturers facilities. Our clean low energy process enables this for the first time ever. This allows companies to tune the thickness of the electrodes easily and make batteries in charged state which increases yield by avoiding the weeks-long formation cycles required for lithium-ion graphite electrodes.

-

There is very little Lithium metal produced! Only 5,000 metric tonnes of lithium metal was produced in 2020. The majority of it was sold under contract to the primary battery manufacturers. Lithium metal is a mere 1% of the lithium market, and lithium chloride, the current precursor to extruded foils, is 3%. The absence of a supply chain is a barrier for companies attempting to commercialize lithium metal batteries, and Pure Lithium solves this problem!

Experts unlocking the potential of lithium metal

Pure Lithium is led by Founder and CEO Emilie Bodoin and Co-Founder and Chief Scientific Officer Donald R. Sadoway, PhD.

Our mission is to get lithium from the ground into a battery as quickly, sustainably, and inexpensively as possible. We develop and scale technology that disrupt both the lithium and battery industries. Pure Lithium’s technology including a non-flammable lithium metal battery dramatically reduces costs and improves quality, supplying the clean energy sector with safe, efficient, sustainable battery technology.